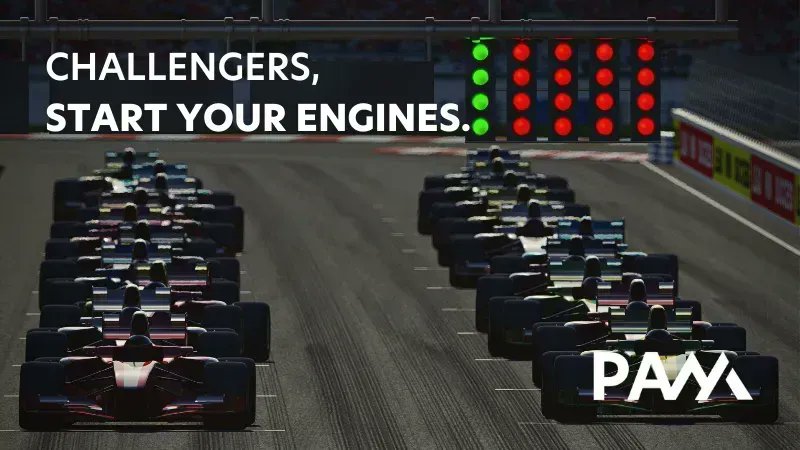

The internet is littered with a lineup of new ‘breakthroughs’, all with engines revving to try and overtake Lithium-Ion in the race to supply viable and scalable batteries for EVs.

But how can they all win? And can any of them really even come close?

One challenger is the Sodium-Ion Battery, a hard carbon electrode with sodium storage capacity. But a look under the hood reveals some early flaws — with a rechargeability of only 1,500 cycles compared to Lithium-ion Batteries at 2,000 to 3,000; and an energy density of only 160 watt-hours per litre, against LIBs at 100-265. What’s more, the Sodium-Ion Battery’s first commercial release was only just last year, in 2021. And we’ll get to the limitations of nascent technology later…

Next, there’s Zinc-Ion — another intercalation-style battery that uses zinc anodes and cathodes. But it’s heavier than Lithium-Ion, making it a drag on speed and energy efficiency; and its rechargeability peaks at around 2,000 cycles, compared to Lithium-Ion’s 3,000 upper limit.

Also in the lineup are Vanadium Redox Flow Batteries (VRFBs), which use vanadium’s ability to exist in four different oxidation states to produce energy from a single electroactive element. When you consider its very low energy density of only 30-40 watt-hours per litre, at least 6x lower than LIBs, you wonder how it even qualifies for the big race.

The only other ‘big’ contender worth a mention is the Dual Carbon or ‘Ryden’ Battery. It’s definitely the most promising rival, but again — its first release was just recently in 2021. And like Sodium-Ion, time is very much against these challengers…

The use of the word ‘breakthrough’ in the context of battery technology is misleading. One look at the frontrunner, Lithium-Ion Batteries, tells us exactly that. In the 30+ years since LIBs were first commercialised, real breakthroughs have been few and far between. As Tesla co-founder Marc Tarpenning notes. “When we started Tesla in 2003, the batteries were just good enough…and we still haven’t had a step change in battery capacity — it just ticks along at 7% to 8% per year.”

So what about new battery tech that starts off with some ‘better’ stats than Lithium-Ion? The simple truth is that high-capacity batteries are complex to say the least; and many approaches that could theoretically double or triple the capacity of LIBs, in practice haven’t been made to work beyond a few charge cycles. Which is why commercial release dates like 2021 (as opposed to 1991) should throw up a red flag. Not a chequered one.

A prime example are Lithium-Sulphur batteries, and there’s a reason they weren’t listed as a serious challenger earlier. On paper, they could have nearly 10x the capacity of current LIB cells. Just one problem: if you make them the same way you make current batteries, they break down almost completely after just one or two charge cycles. So there’s a very long stretch of development road to before they even turn a corner. And while that’s happening, LIBs are lapping them.

The harsh reality of time as a key, and often missing ingredient, is also true for other so-called tech ‘breakthroughs’. Real results take decades from inception. Look at AI, for example. It’s easy to fall for all the media hype. For decades, experts have been predicting that computers will soon have human-like intelligence. But even today, that vision is far from reality.

In 2016, legendary American computer scientist Geoffrey Hinton said of Radiology AI, “We should stop training radiologists now, it’s just completely obvious within five years deep learning is going to do better than radiologists.” Since these words, the number of radiologists working in the US has gone up, not down, and there’s even a shortage of radiologists that’s expected to deepen.

And back in the automobile industry, it’s also worth noting that peak innovation occurred over 100 years ago in 1914. In no year since, have more manufacturers entered the market. The point being that most innovation occurs at the start of a technology, like it did for solid state batteries — back in 1985 when Lithium-ion Batteries were invented and later commercialised in 1991. It takes decades to reach real commercial viability. And for tech with a 30-year head start, the race is practically won.

So what would a real contender need to turn up with? Qualification is tough, because Lithium-Ion is already a major step up from any previous commercial battery technology. A serious challenger would need to match, if not beat, LIBs’ energy density, rechargeability, raw material and manufacturing costs, safety and scalability — all at once. And keep getting better, like Lithium-Ion Batteries are doing.

And in addition to the harsh realities of time, there’s also the other wake-up call: money. With the amount of capital already invested in Lithium-Ion manufacturing, a challenger would likely need to be compatible with, and preferably simplify, the Lithium-Ion manufacturing process. Relying on a new method of production will only serve to slow the technology down even more. And as the Lithium-Sulphur example shows, it’s not easy to stay in Lithium-Ion’s slipstream.

Let’s look at some of the enormous sunk capital so far…

Since 2020, Chinese company QingTao has had a production line for solid state batteries with a capacity of one gigawatt-hour per year — and Neta and BAIC have already used their batteries in their EV prototypes.

While over in California, Mullen Technologies aims to equip their second generation ‘Five’ electric SUV with solid state Lithium-Ion batteries, and is aiming for initial vehicle tests with the tech in 2025.

At the same time, Li-Metal — a Canadian Lithium metal anode company, has signed a development and marketing agreement with Bolloré subsidiary Blue Solutions for battery anodes, with further plans for a joint anode plant.

To name a few…

It’s just an economic fact that when vast amounts of money are already invested in a promising technology with multiple wins on the leaderboard, a challenger with a new manufacturing process has a far harder job to do. As the adage goes, it’s like turning a battleship.

All of which places Lithium explorers like Pan Asia Metals (ASX:PAM) in pole position to capitalise on the advanced evolutionary state of Lithium-Ion Batteries. A technology that’s already decades ahead. While its challengers haven’t left the starting grid.

Written for Pan Asia Metals by Josh Bryer